Lean Principles

Womack, Jones and Roos published two successful books entitled ‘The machine that changed the World’ (1990) and ‘Lean Thinking’ (1996). Both books address the revolution in manufacturing represented by the Toyota Production System of the Toyota Corporation of Japan. They compared this way of working with the traditional mass production system that was used by other companies in the Western world. They described in their book ‘Lean Thinking’ the following five principles:

- Value: Define what is of value to the customer

- Value stream: Identify the value stream and eliminate Waste

- Flow: Create a constant flow

- Pull: Deliver based on demand

- Perfection: Continuously improve the process

Waste

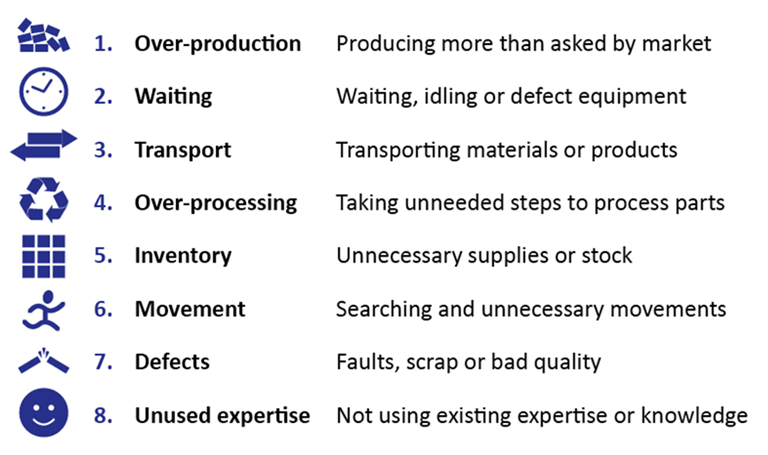

Within Lean, identifying and eliminating waste is one of the most important activities. Wastes are also referred to as Muda. We distinguish eight forms of Waste, which are listed in the figure below. Lean contains several techniques to eliminate Waste. Besides eliminating Muda (Waste), Lean also focus on reducing Muri (Overburden of machines and people) and Mura (Unevenness).