Six Sigma Principles

Understanding the core principles of Six Sigma and variation control

The main focus of Six Sigma is to reduce variation in order to improve the quality of a product or process. Variation is everywhere. A driver has variation when parking his car; the arrival times of trains have variation; the human race shows enormous variation and products extracted out of a process are never the same. Every process demonstrates variation. The less variation a process has, the better we can predict its outcome and control the level of defects produced. Therefore, Six Sigma has a strong focus on reducing variation. If we want to base our decisions within problem-solving projects on facts, we have to know how to analyze and interpret data.

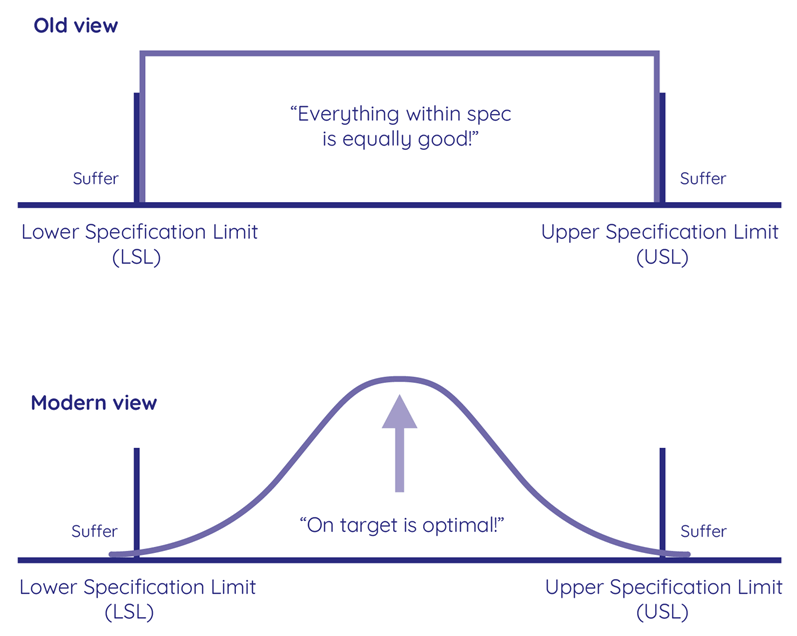

The difference between the so-called ‘Old view’ of variation and the ‘Modern view’ of variation is shown in the figure. The old approach is about approving the product when it meets the specification and rejecting the product when it does not meet the specification. There were only good and bad products. A much better way of looking at products meeting specification is to realize that a product that is exactly in the middle of the specifications is better than a product that is very close to one of its specification limits. Furthermore, a process that demonstrates little variation is better than a process that demonstrates a lot of variation.